Birds, bubbles and spiders:

Drawing inspiration from the natural world to develop new solutions to aquatic environmental challenges

November 2022

Introduction

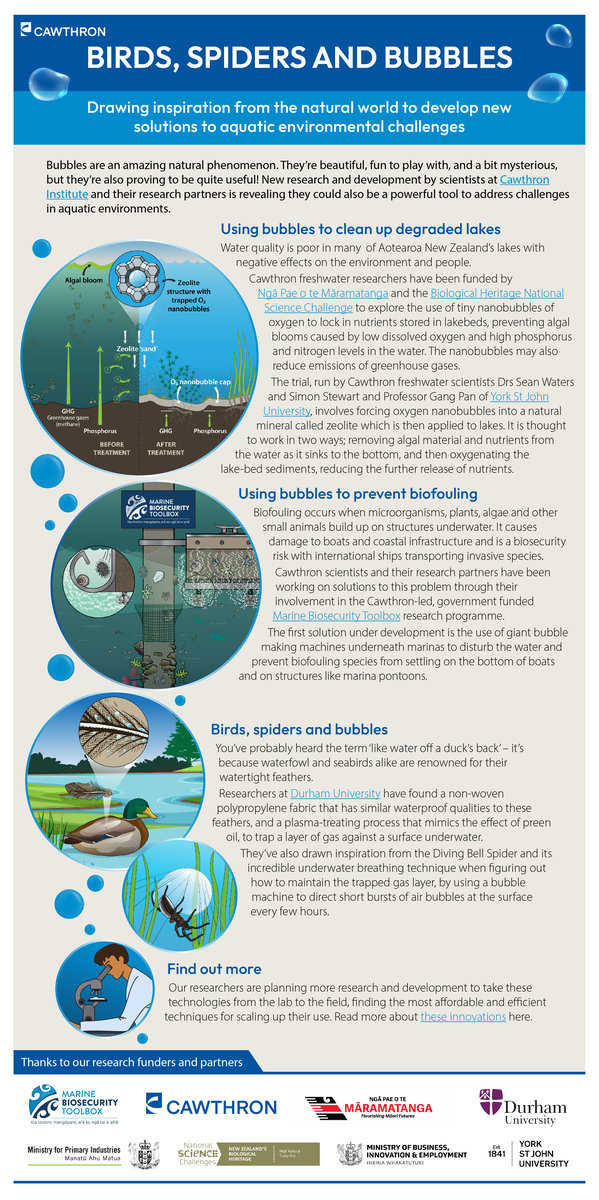

Bubbles are a natural phenomenon which have long captivated human imagination and creativity due to their beauty and mystery, but new research and development is revealing they could also be a powerful tool to address challenges in aquatic environments.

Researchers at Nelson’s Cawthron Institute have begun to explore the wide-ranging potential of bubbles as solutions to challenges in both marine and freshwater aquatic environments, with two new areas of research focus including the use of bubbles to bring life back to stagnant or eutrophic lakes and as an antifouling solution in ports and marinas to protect underwater structures from biofouling organisms.

Why bubbles?

A bubble is generally a pocket or ball of gas trapped within a liquid, but bubbles can also form as balls of air surrounded by liquid, like soap, that float in the air.

Bubbles contained within liquid do a few key things. They move gases like oxygen and nitrogen and particles of matter around in the water column, and they attach to surfaces submerged in the water, forming a barrier that can be water-proof.

So how could we use bubbles as a secret weapon in aquatic environments?

Recent research has suggested that there are a few key ways that the attributes and function of bubbles could be harnessed to our advantage in aquatic environments.

Firstly, we could use tiny nanobubbles of oxygen to lock in nutrients stored in lakebed sediment, preventing the algal blooms caused by low dissolved oxygen and high nitrogen and phosphorus levels in the water and reducing the release of greenhouse gases such as methane.

Secondly, Cawthron researchers have explored the use of bubbles in marine aquatic environments to prevent biofouling. By generating bubbles in short bursts that create disturbance beneath underwater structures, researchers have successfully prevented biofouling organisms from attaching to them.

And finally, drawing on studies of the diving bell spider’s use of air pockets for underwater respiration and the water-proofing properties of seabirds and waterfowl, Cawthron researchers have worked with partners at Durham University to find materials that replicate these natural defense mechanisms by trapping pockets of air on surfaces underwater to create protective barriers.

Water quality is poor in many of Aotearoa New Zealand’s lakes, negatively impacting lake ecology as well as cultural, social and economic values. A lake is labelled ‘eutrophic’ when it has too many nutrients like phosphorus and nitrogen which are often fed into the lake through human activity on surrounding land. One result of this can be low dissolved oxygen levels in the lake waters.

Efforts to restore lake ecosystems by reducing the flow of nutrients from the catchment have often had very slow effects because of ‘internal’ nutrient loads stored in lake sediments. When oxygen concentrations are low these nutrients are released from bottom sediments into the water column, maintaining poor water quality and fueling algal blooms for years or even decades afterwards.

Furthermore, attempts to control these ‘internal’ nutrient loads have often relied on ‘geoengineering’ products which bind nutrients or physically block their release from the sediments to the water. These have also had mixed success and concerns remain about toxicity and whether it is culturally acceptable to add ‘chemicals’ to lakes.

For these reasons, the search continues for more environmentally friendly methods of reducing the release of nutrients and greenhouse gases from lake sediments.

With the support of partners like the Biological Heritage National Science Challenge, and Ngā Pae o te Māramatanga (New Zealand’s Māori Centre of Research Excellence), Cawthron Institute freshwater scientists Drs Sean Waters and Simon Stewart have been working with York St John University’s Professor Gang Pan to investigate the use of nanobubbles as a tool to deliver oxygen to sediments, stopping the development of low oxygen conditions and the accompanying release of nutrients.

Waters say that nanobubbles of oxygen are tiny bubbles formed (<1000nm) at the interface of solid surfaces and liquids.

“They’re not really that visible in the water, but if you can imagine them being like the tiny bubbles that sometimes appear in a glass of water and stick to the side of the glass, they’re like that but smaller.”

“Our team completed an initial desktop study that was funded by Ngā Pae o te Māramatanga because they were interested in whether or not nanobubble technology could be a potentially eco-friendly solution for Māori to use in lake restoration.”

“We found that while globally this research is at a very early stage, there could be great promise in some of these techniques so we’re eager to build on that.”

Waters says the studies they reviewed revealed that when used alongside a product known as a flocculant (a substance that can be added which causes particles of matter to clump together), nanobubbles may provide an environmentally friendly method to strip water column nutrients and prevent the re-release of nutrients and methane from the lakebed sediments.

“The promise of this concept has been demonstrated in a small number of preliminary laboratory-scale studies but there is more work to do, so we’ve launched a new project funded by the BioHeritage National Science Challenge to further develop this technology at bigger scales and explore its potential for restoring Aotearoa New Zealand’s degraded lakes.”

Waters says the key objectives of this new project will be to develop the capability to produce oxygen nanobubble carrying material for lake restoration in New Zealand for the first time.

“We hope to use minerals called zeolites as flocculants but also as ‘carriers’ of the nanobubbles. To do that we need to treat them in a vacuum followed by a high pressure, pure oxygen environment which forces the oxygen nanobubbles onto the mineral surfaces.”

The next step will be to test how effective this approach is as an oxygenating sediment cap in a preliminary core-scale laboratory trial followed by a move up to a pond-scale trial.

“In doing that, we’d really be aiming to answer key questions about the approach, like for example whether nanobubbles can substantially decrease nutrient release from lakebed sediments in a real-world setting, and how long would this suppression of nutrient recycling last?”

Preventing biofouling on underwater structures in marine environments

Biofouling occurs when microorganisms, plants, algae and other small animals accumulate on structures underwater.

Although a natural occurrence in marine environments, it is a problem for marine industries and owners of coastal and offshore infrastructure like ports and marinas.

biofouling causes damage to underwater surfaces, can interfere with the performance of moving parts, and creates drag on vessels. It can also create attractive surfaces for non-indigenous pest species to settle on, aiding their unwanted spread.

Video: Cawthron Institute. Researchers install a bubble machine beneath Waikawa Marina in Picton as part of a trial.

The development of solutions that prevent biofouling development of submerged infrastructure is one of the key objectives of the Marine Biosecurity Toolbox, a research programme funded by the New Zealand government.

Cawthron’s Healthy Oceans Manager, Dr Grant Hopkins, leads the antifouling technology development in the Toolbox programme and is involved in a number of research projects with colleagues at Cawthron that aim to develop biofouling solutions.

“This is a global issue that causes major losses in productivity and creates environmental and biosecurity threats, and it’s not being effectively managed because the solutions just aren’t available yet, and that’s something our researchers in the Toolbox team and at Cawthron are very keen to change,” Hopkins says.

“What we are confident of is that bubbles are really effective at preventing biofouling – we published a study in 2020 after a year of laboratory and field trials which showed that bubble streams can not only stop organisms from settling on surfaces but can also remove recently settled larvae, which is great.

“What we are confident of is that bubbles are really effective at preventing biofouling – we published a study in 2020 after a year of laboratory and field trials which showed that bubble streams can not only stop organisms from settling on surfaces but can also remove recently settled larvae, which is great.

“What we are now working on is the development and testing of bubble producing systems, and this is tricky work!”

“Do you just put bubble diffusers beneath a structure that requires constant electrical supply and continuously blast a stream of gas at the surface, or can you do it periodically, and if so, at what intervals?”

“Or, are there ways of trapping pockets of gas against these surfaces to create a protective barrier? There are plenty of questions and avenues to explore, so we’re working on a few, with a new trial about to start at Port Marlborough in the coming months.”

The latter approach Hopkins mentions – trapping gas at the liquid-solid interface – is a specific avenue he and his colleagues are exploring.

“You’ve probably heard the term ‘like water off a duck’s back’ – it’s because waterfowl and seabirds alike are renowned for their buoyancy and watertight coat of feathers.”

“We’ve been drawing inspiration from this and working alongside some world-leading experts at Durham University in the UK to explore whether some of these features could be replicated to create special protective coatings for underwater structures that would prevent biofouling.”

“Through a combination of the structure of their feathers, which have special interlocking barbs and hooklets that fuse together and trap a protective layer of air called a plastron against the bird’s skin, to the waterproof preen oil that coats the feathers to further repel any moisture, waterfowl are a clear example of nature’s genius.”

Professor Jas Pal Singh Badyal of the Department of Chemistry at Durham University says their team of researchers are not the first to explore this idea, and other researchers have tried to create materials that mimic the waterproof properties of the coats of waterfowl using a variety of fabrication techniques.

“They have used techniques like electrospinning, 3D printing, laser cutting and producing special plastics with modified surfaces to mimic the coat’s fabrication, but they haven’t addressed how these coats trap air pockets at the solid-liquid interface, which is the key part we are interested in,” Badyal says.

“There have been studies which have shown that trapped gas layers on the surface of underwater structures can be a very effective way of preventing the attachment of bacteria and reducing drag if that surface is the hull of a boat, but no one has figured out how to maintain these trapped gas layers for a long period of time.”

“They’ve tried creating special materials and heating them to trap a gas layer at the surface, they’ve tried creating an electrical current on the surface which produces a hydrogen bubble, they’ve applied steady gas pressure from behind the surface of a special water-proof material… none of these approaches have produced viable solutions yet.”

Badyal says one of the key challenges with the approaches trialed so far is that they require a continuous supply of electrical power to maintain, have complex construction, and they do not provide complete coverage of the surface area.

“What we were able to do was find a special kind of non-woven polypropylene fabric with similar water-resistant properties to that of a mallard duck’s feathers, cover it in a substance that is similar to preen oil, and use it to create what we call a ‘substrate’ which is basically just a kind of surface coating or cover for an object.”

“After lots of tests in the lab, we could conclude that it had similar properties and would be as effective as keeping out water, but we needed to figure out how to combine that material with a method of maintaining the trapped gas layer too, and so we looked to another natural source of inspiration – the diving bell spider.”

Badyal says the diving bell spider possesses a remarkable underwater respiration technique that enables it to spend most of its life underwater, even though it requires oxygen to survive. It found a way to breathe underwater by maintaining a large bubble of oxygen that it secures either to itself, or to underwater foliage that it lives on, with a special silk web. The spider regularly returns to the surface to trap more air in a bubble on its abdomen and top up the oxygen supply it has stored underwater.

“What the spider can teach us is how to extend the lifetime of a trapped gas layer. Our theory was that if we mimicked its approach and directed a short solar-powered burst of air bubbles at our underwater surface that was covered in the polypropylene substrate once every 2 hours, this could effectively maintain a trapped gas layer on the underwater surface.”

“We were able to use these techniques in trials to produce stable gas layers over long periods of time and effectively inhibit biofouling.”

So with an effective solution identified, what are the next steps?

Fellow study contributor Dr Patrick Cahill, of Cawthron Institute, says these study results, which have now been patented by Cawthron and Durham University, prove that their combined nature-inspired approach holds significant potential for eco-friendly antibiofouling without collateral harm to the environment.

“Our next steps are to do further research and development to establish methods for scaling this technology up and testing it in real-world environments.

“We’re particularly keen to test this on boat hulls in marinas – if it all comes together as we hope, this could be a transformative anti-fouling solution with application across a variety of marine industries.”