Case Study: Challenge testing a new product for Kraft-Heinz

November 2024

Cawthron Laboratories offers a full spectrum of food safety testing services to a variety of clients in the food and natural products industry, from fresh seafood products to products like milk powder and condiments.

Challenge Testing is one of our standard food safety testing procedures that aims to check whether a product is adequately preserved and won’t spoil for the duration of its intended shelf life.

It involves inoculating the product with specific spoilage organisms to monitor their levels over a defined period. This ensures that product alterations maintain high standards of quality and safety throughout their shelf life.

Working with Kraft-Heinz

Kraft-Heinz is a major global food producer and product developer who are always looking to create new flavour combinations for their iconic range of condiments. Any significant recipe change in their products undergoes rigorous challenge testing to assess its impact on shelf life and resistance to potential contaminants.

In 2024, Kraft-Heinz approached Cawthron Institute with a recently developed product for challenge testing to ensure it would stand up to the rigors of consumer usage. David Lim, Science and Regulatory Affairs Lead at Kraft-Heinz ANZ said the company’s consumers are at the centre of everything they do.

“We are building a culture of creativity to anticipate and respond to their future needs, delivering appetizing food across our brands which is safe and of the highest quality.”

“Our customers are at the centre of everything we do. We are building a culture of creativity to anticipate and respond to their future needs, delivering appetizing food across our brands which is safe and of the highest quality.”

The challenge:

Cawthron maintains a repository of known spoilage organisms specific to different food types including products with low pH, high salt, and high sugar content. Appropriate organisms were selected by Kraft-Heinz to use including yeast and lactic acid bacteria. The organisms were introduced to the new product and a reference product in a known concentration and then tested periodically over the course of 12 weeks using IANZ accredited enumeration methods.

Findings:

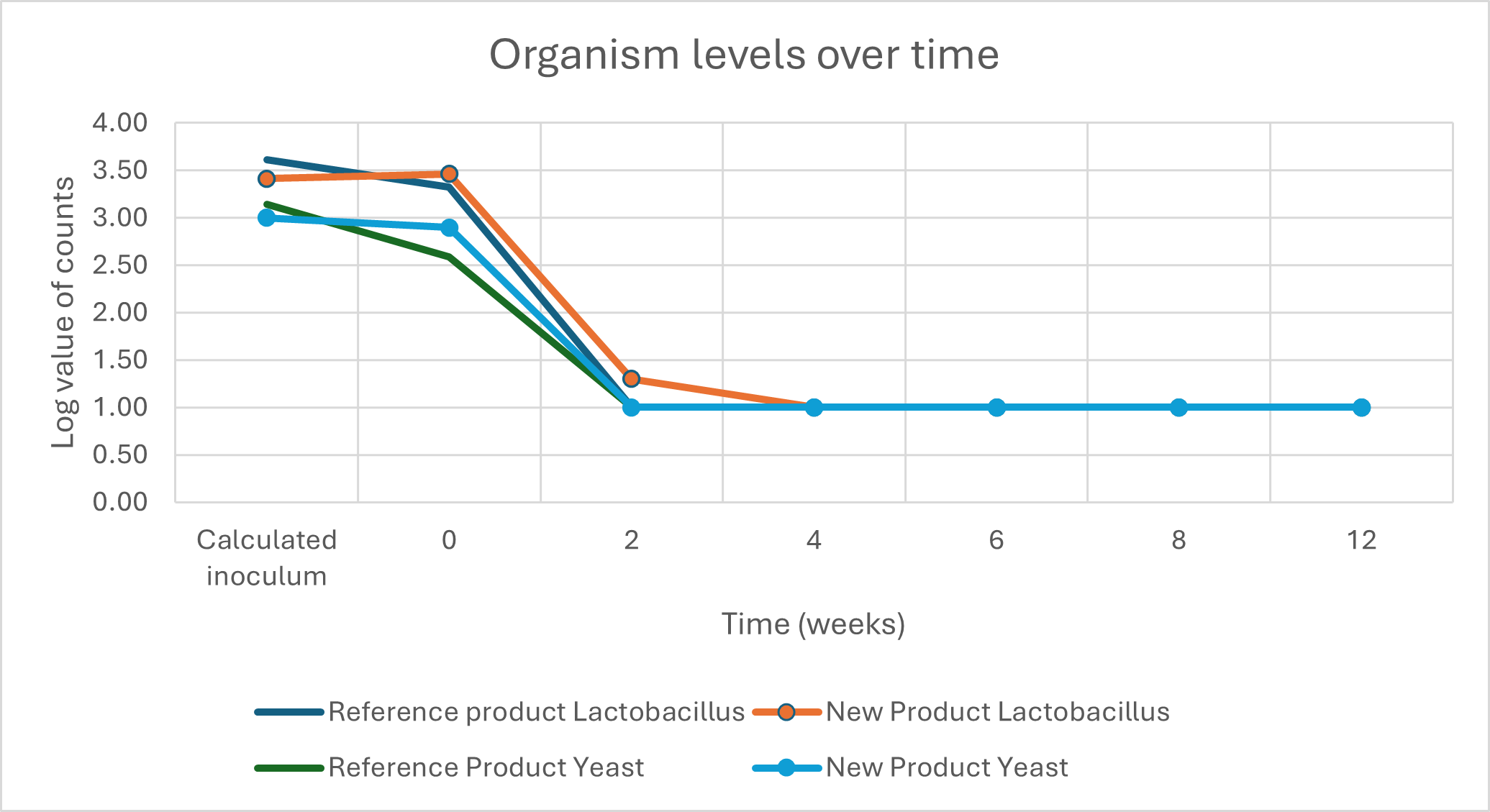

The results from the new product were compared to the results from the reference product.

The results show that the organisms introduced to the new product have decreased in concentration low levels, matching the reference product therefore passing the acceptance criteria expected from Kraft-Heinz.

Impact:

Kraft-Heinz now has robust data confirming the shelf-life stability of their new product. This information provides confidence in the new product’s performance, both in the marketplace and in the hands of consumers.

“We are a company of food lovers and at the core of or values is being consumer obsessed. Our dedication to quality and innovation ensure that consumers have unwavering confidence in our products,” said Lim.

Cawthron Laboratories Microbiology Team Leader Mark Englefield said the challenge testing process is an essential part of New Zealand’s food system.

“Food producers have to meet the required food safety standards under New Zealand’s regulations to sell products to consumers here, but also if they want to export overseas, so it’s a really essential part of our food system,” Englefield said.

“As a testing provider to food companies, our goal is to provide tailored testing services with flexible, wrap-around administrative and technical support so that we can meet each customer’s unique needs, including time-frames which can often be short or changeable.”

“As a testing provider to food companies, our goal is to provide tailored testing services with flexible, wrap-around administrative and technical support so that we can meet each customer’s unique needs, including time-frames which can often be short or changeable.”